Last Updated on January 20, 2021 by Staff

As hinted in our Mark-and-Go license agreement, we intend to make patent-pending ergonomic and training marcosticks available for everyone to print, for free. During research we made prototypes with a carving knife, epoxy putty, plain chopsticks, and some piano wire. After filing two utility patents, we are now making 3D models, to reproduce these enhanced chopsticks by 3D printing. Once we are happy with these, we’ll make models available.

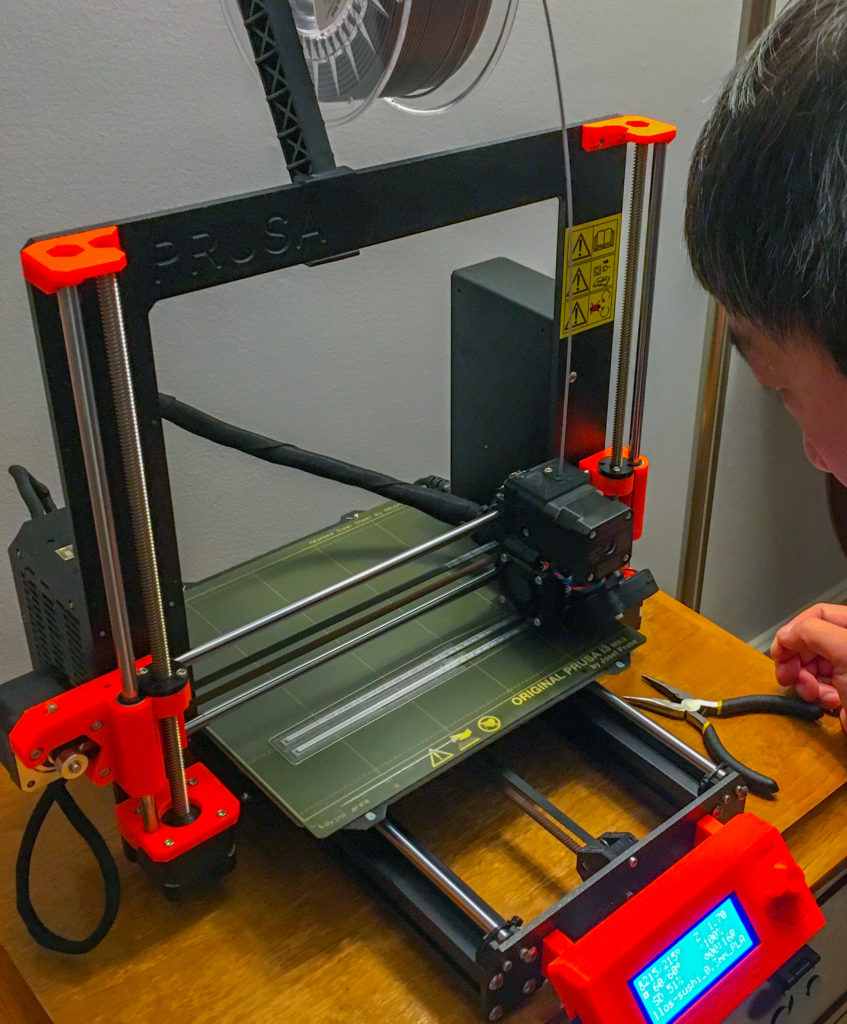

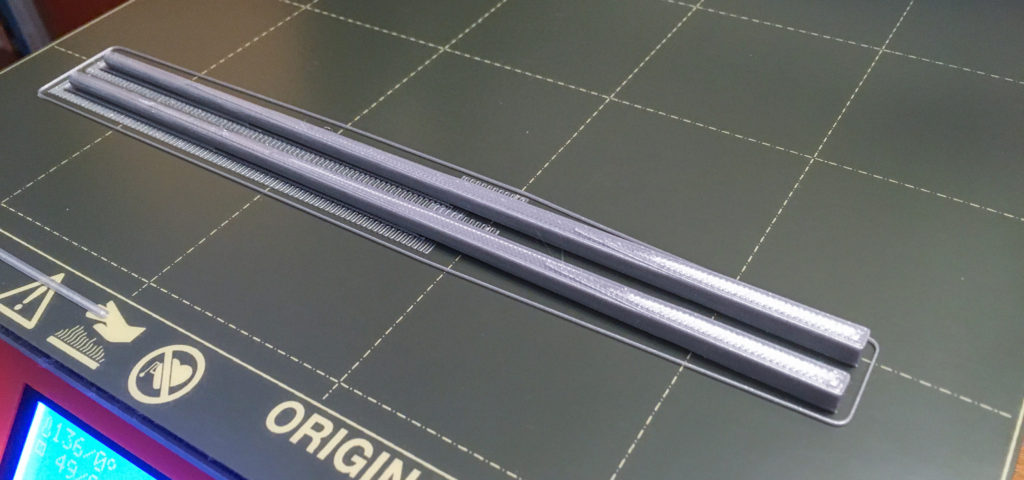

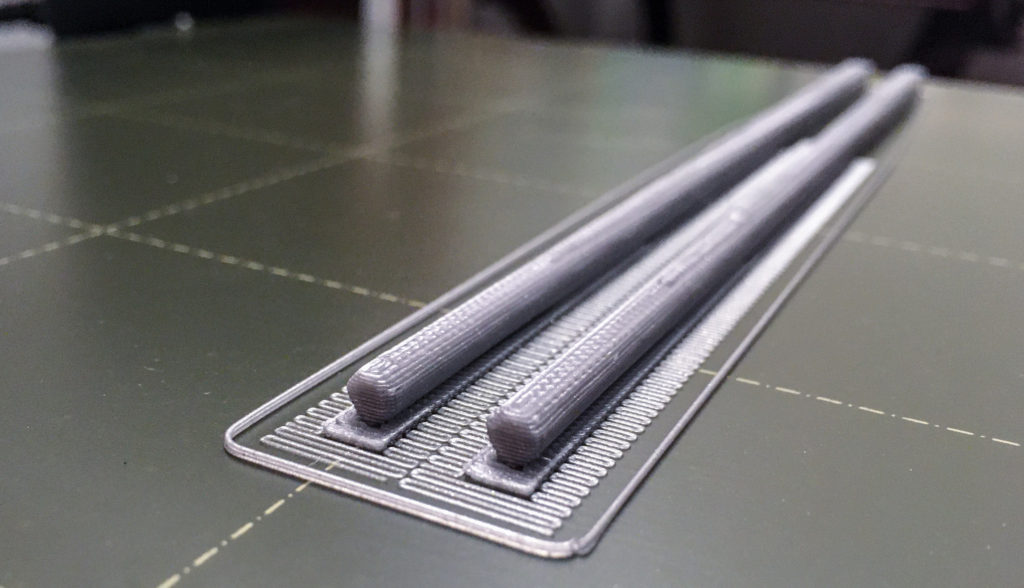

What you see here are your run-of-the-mill chopsticks, not the enhanced versions. We just received the 3D printer last week. At the moment we are still figuring out how to make good prints. We have printed a few interesting objects so far, including plain chopsticks from model files uploaded by Caracolmaker.

We printed these chopsticks with SLA at 0.3mm layer height. Since it was just a test print we left the infill at 20% and used draft mode settings.

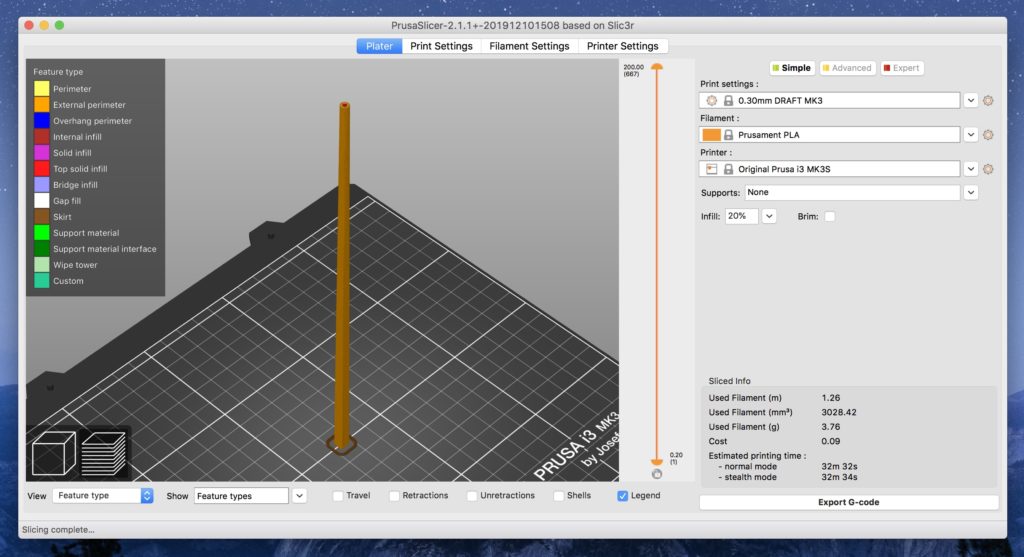

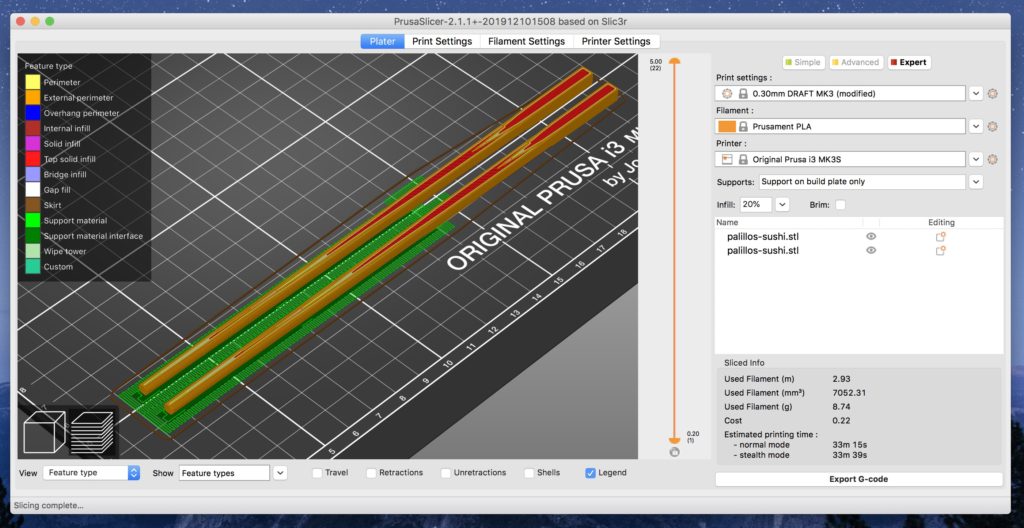

The STL model from Caracolmaker came with the stick standing on its rear end. This is not the best way to print chopsticks. With a tiny base sitting on the printer bed, and a tall stick flexing at the top, it would not have come out well.

The challenge here was about how to best print these sticks. A chopstick is tapered at the tip. This creates an extensive overhang which is enemy number one of 3D printing.

One way to solve this problem is to cut a chopstick in half along its longitudinal axis. The two halves are printed with the cross section facing the print bed, and then glued togeher after printing. That’s too much trouble. Instead, we added support material to prop up tips of the two chopsticks in PrusaSlicer.

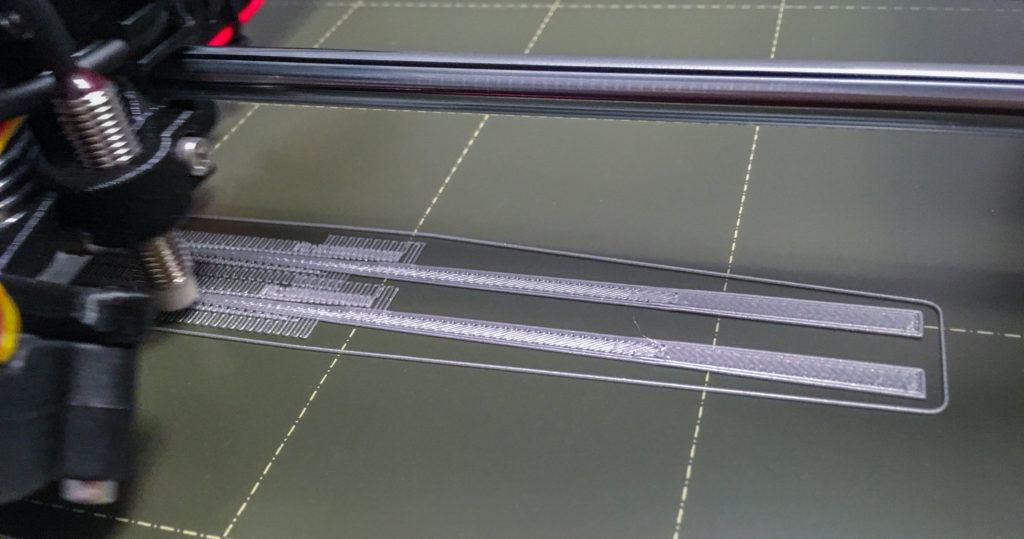

Below is a picture of the print bed after a few layers.

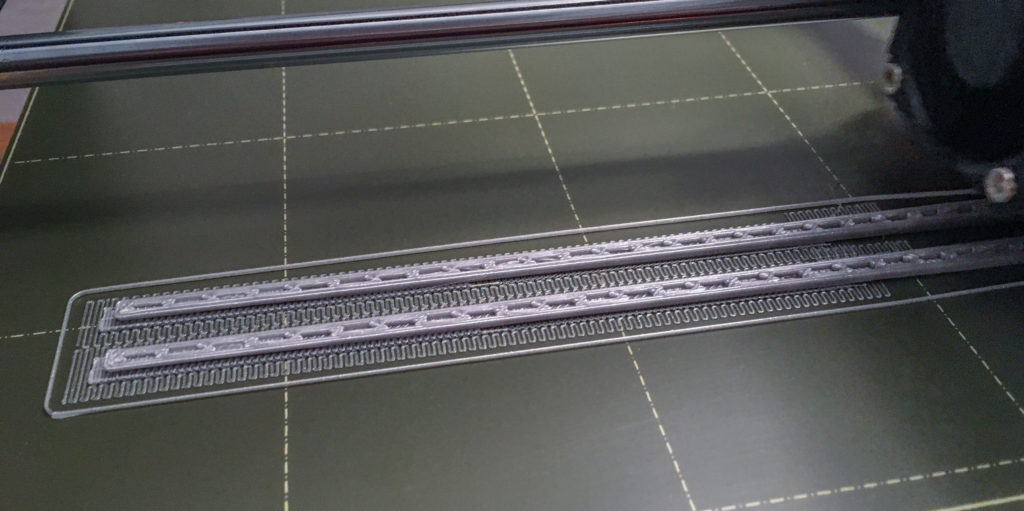

We are half way there:

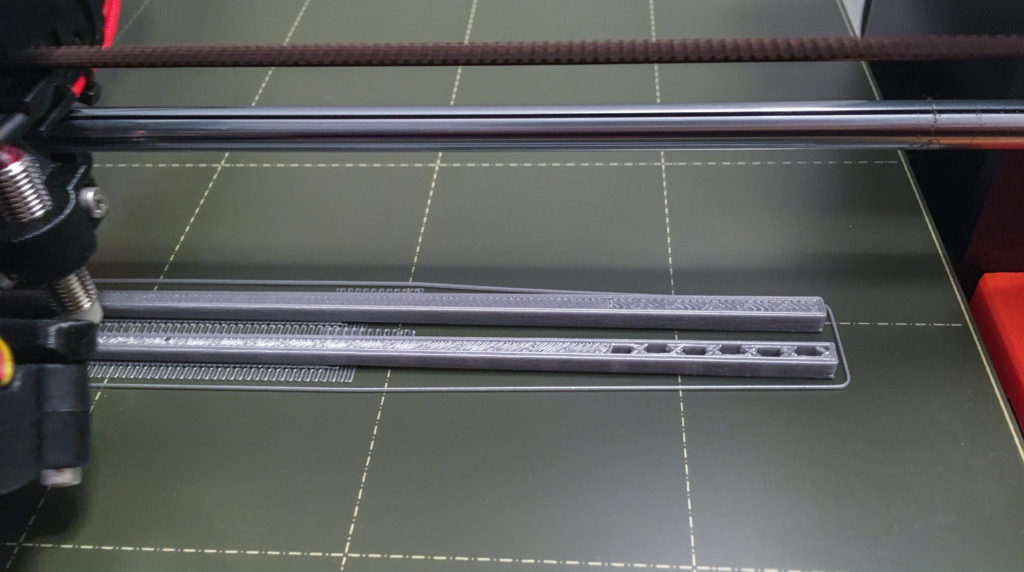

Just about done:

They are printed successfully!

We do not intend to use these printed chopsticks yet. They are printed with PLA at coarse grain and are not sanded. They contain crevices that harbor bacteria, so they are not suitable for actual use. In general one would use PETG for actual use.

In any case, PLA at 20% infill with 0.3mm layer height is too soft for chopsticks. Watch how these sticks bend at medium pressure.

Well… that’s it for now. We’ll be busy working on 3D models of enhanced chopsticks next. Stay tuned.